AT BELL LABS IN MURRAY HILL, THE FUTURE OF INDUSTRIAL AUTOMATION IS ALL ABOUT THE NETWORK

|

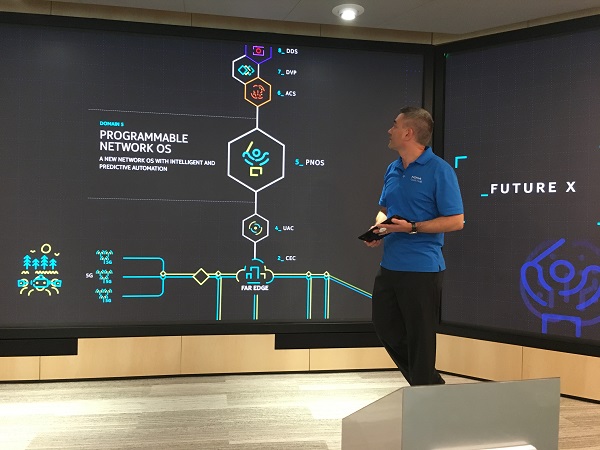

| Marcus Weldon introduces Future X for Industries | Esther Surden |

In November, NJTechWeekly.com was among a small group of journalists who were given a first look at some new industrial automation/internet-of-things (IoT) technology at Nokia Bell Labs in Murray Hill.

The technology was both described by officials and demonstrated by engineers at a recently built laboratory at Bell Labs.

Using the laboratory, enterprise customers of the company’s newly announced Future X for industries strategy and architecture will be able to envision how slicing, fine-tuning and making changes to their industrial networks will help them achieve their goals. Need less latency in a robotic task? The network will adapt for that. Need more speed for another task? The network will adapt.

First they’ll sit down in a futuristic network control center and see what tweaks can be made to change their productivity outcomes. Then, they’ll virtually tour a simulated factory floor that harnesses industrial-IoT, distributed-cloud, augmented-intelligence (AI), augmented-reality, virtual-reality and high-performance networking, including advanced LTE and 5G.

Nokia Entering New Markets

Nokia is entering new markets with these AI-infused industrial networks, we learned at the press briefing. The briefing included presentations by Marcus Weldon, president of Bell Labs and CTO of Nokia; interviews with representatives of Nokia’s marketing and sales teams; and a tour of the Bell Labs Future X for industries network facility, where the company demonstrated its capabilities.

According to Weldon, networks need to become more dynamic, more scalable and more economical. They also need to create more value, and the driver for all these changes will be industry: infrastructure developers, manufacturers and enterprises.

“We’ve looked at what will serve industrial needs in detail,” he said.

One of the main components of this IoT network will be network slicing. “I’m not talking about any ordinary QoS [Quality of Service], I’m talking about QoS like you wouldn’t believe,” said Weldon.

AI and IoT for a New Industrial Age

As we enter into this new Industrial Age, all applications and services in every industry will need QoS, he noted. Applications and services will have to be dynamically adapted and managed because things keep moving, so QoS will continue to be necessary. Networks will have to adapt to a changing environment if, for example, a robot is switched out or a new sensor added. Business systems also have different monthly habits, as well as different habits for various times of the day, and these will have to be accommodated. This adaptation is already becoming more tangible, real and important, Weldon said.

The market for industrial IoT is “hyperbolically large,” Weldon said, possibly $11 trillion of new value creation over the next 10 years. “If you can solve an $11 trillion problem, and 10 percent of that can come to those who solve the problem, you can imagine that this could be something that’s as large as the current industry we are in.”

“Industry is stuck at current levels of productivity. It will need a network to fix this.”

With a constantly changing network as the backbone of a new industrial application, operations technology and information and communications technology can come together. “The network infrastructure is probably the toughest part of the problem because it is a physical thing that you have to put in, dig, put things up on poles.” Until now, there hasn’t been any reason to make this happen, he said.

But now there is a reason. “Industry is stuck at current levels of productivity. It will need a network to fix this.” Weldon added that customers had come to Nokia asking if the company could fix their production environment, as Wi-Fi wasn’t working.

“No matter how many versions of optimized Wi-Fi they had deployed, it wasn’t reliable enough, didn’t have low enough latency, didn’t have enough capacity,” he said. And he noted that the enterprise business is a natural for Nokia because its sales team can operate through service provider partners or on its own, and the company has teams in many different countries worldwide.

Visitors to the lab will be able to configure their networks live and to experience an emulator that recreates factory-use cases in an Imax-like theater environment. Nokia has also built a small factory that does assembly tasks, and has constructed a small city that allows it to demonstrate the flying- or moving-vehicle features of the future IoT. The demonstrations test the end-to-end performance of a network and how the network can be dynamically adapted to a representative task. Once particular network configurations are pinned down, Nokia will be able to port them to a customer’s location more easily.

Some of what is being demonstrated in Murray Hill came from technologies developed by San Mateo-based SpaceTime Insight, which Nokia acquired in May, but these technologies have been combined with technologies developed at Bell Labs. At the time of that acquisition, Nokia said SpaceTime Insight’s advanced IoT and machine learning-powered analytics technologies would accelerate the development of Nokia’s IoT offerings.

>

Esther Surden is Publisher and Editor of NJTechWeekly, and a contributor to Philly Tech News. This article originally appeared in NJTechWeekly , and is republished here with her permission.

No comments:

Post a Comment